3D printer comparison table

Dual material / dual extrusion printers compared.

Sortable table with a lot of information Scroll Right and Down. Click the headers to sort columns, eg Price, Width of Build Plate or Type of Print Surface.

Hover over a cell for extra detail.

| Dual Extrusion 3D Printer Comparison | Scaled image | Price £ Inc Tax | Dual Extrusion system | Stringing / Blobs | Nozzle lift | Seconds to swap material | hh:mm:ss added to example DM print | Printer Width mm | Printer Depth mm | Printer Height mm | Fully enclosed | Dual Extrusion Build Width | Dual Extrusion Build Depth | Dual Extrusion Build Height | Unboxed Weight. kg | Material waste per print % | Type of waste | Print Surface | Number of prints between maintenance | Removable | Flexible | Materials | 3rd party materials allowed? | 1.75mm Filament compatible | External filament feed | Dedicated material dehumidifier | Structural Material | ABS | Nylon | PETG / CPE | Abrasive filled | Flexible | Support Material | Water soluble PVA base eg PVOH/BVOH | Peel away | HIPS | Ethanol / diluted acid soluble | Software / Service | Software Included | Warranty length months | UK service centre | Connectivity | LAN | Wifi | Direct USB | SD card or USB stick | Automation | Levelling | Adaptive mapping | Material setting | Error resolution | User notification | File sending | Print statistics logging | Safety | HEPA Filter | Carbon Filter | Locking door | Automatic unlock |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

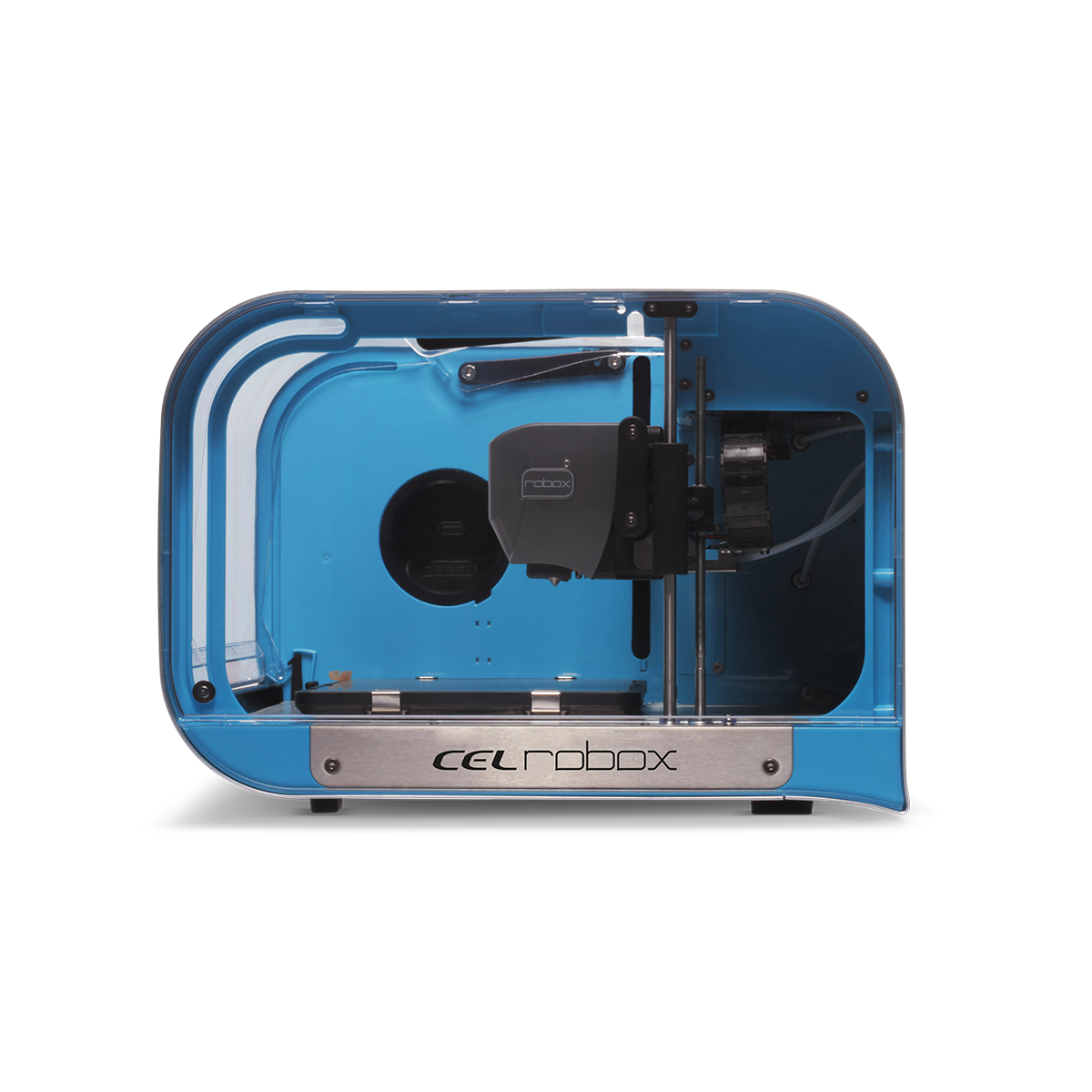

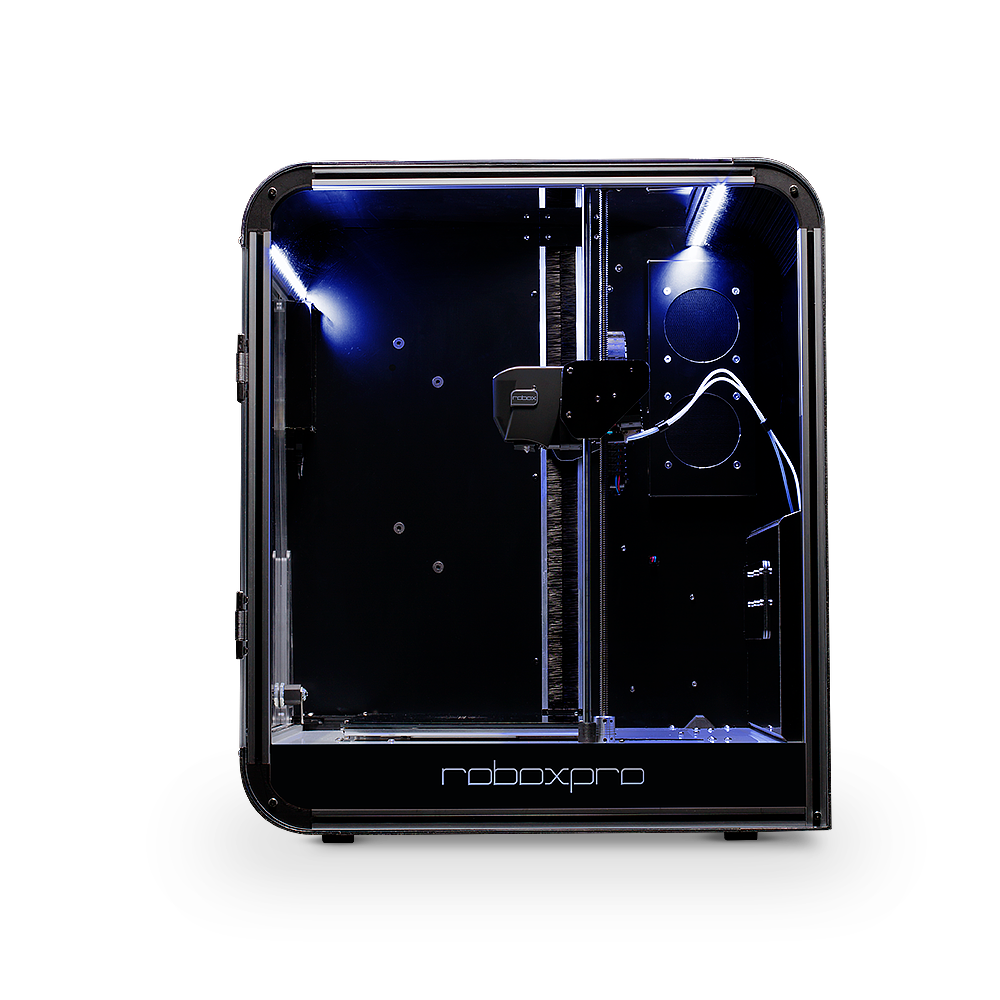

| Robox RBX10 |  | £3699.00 | Close Valve + Rotate | No | Yes | 0.4 | 00:06:40 | 513 | 508 | 605 | Standard | 300 | 210 | 400 | 16 | 0% | None | Sprung Steel + Thick PEI | 500+ | Yes | Yes | Yes | Yes | Yes | Optional (+£600) | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | 12 / 36 | Yes | Yes | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |||||||

| Robox RBX02 |  | £1119.90 | Close Valve + Rotate | No | Yes | 0.4 | 00:06:40 | 410 | 340 | 240 | Standard | 210 | 150 | 100 | 10.8 | 0% | None | Thick PEI | 500+ | Yes | Yes | Yes | Yes | Yes | Optional (+£600) | Yes | Yes | Yes | Optional Head (+£160) | Yes | Yes | Yes | Yes | Yes | Yes | 24 / 36 | Yes | Optional (+Root £110) | Optional (+Root) | Yes | Optional (+Root) | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Optional (+Extractor £350) | Optional (+Extractor) | Yes | Yes | |||||||

| Ultimaker S5 |  | £6114.00 | Passive Hotend Swap | Yes | Yes | 9 | 02:30:00 | 495 | 457 | 520 | Optional (+£384) | 330 | 240 | 300 | 20.6 | 30% | Wipe tower | Glass + Glue | 1 | Yes | No | Yes | No | Yes | No | Yes | Yes | Yes | Optional Head (+£330) | Yes | Yes | Yes | Yes | No | Yes | 12 | No | Yes | Yes | No | Yes | Yes | No | Yes | No | No | Yes | No | No | No | No | No | |||||||

| Ultimaker 3 |  | £3354.00 | Passive Hotend Swap | Yes | Yes | 9 | 02:30:00 | 342 | 380 | 389 | Optional (+£360) | 197 | 215 | 200 | 10.6 | 30% | Wipe tower | Glass + Glue | 1 | Yes | No | Yes | No | Yes | No | Yes | Yes | Yes | No | Yes | Yes | Yes | Yes | No | Yes | 12 | No | Yes | Yes | No | Yes | Yes | No | Yes | No | No | Yes | No | No | No | No | No | |||||||

| Makerbot Method |  | £5999.00 | Powered Hotend Swap | Yes | Yes | 8 | 02:13:20 | 649 | 413 | 437 | Standard | 152 | 190 | 196 | 29.5 | 30% | Wipe tower | ABS | 1 | Yes | Yes | No | Yes | No | No | No | No | Yes | No | No | Yes | No | No | No | Yes | 12 | No | Yes | Yes | Yes | Yes | Yes | No | Yes | No | Yes | Yes | Yes | Yes | No | No | No | |||||||

| Zortrax Inventure |  | £2326.80 | Powered Hotend Swap | Yes | Yes | 20 | 05:33:20 | 350 | 345 | 405 | Standard | 135 | 135 | 130 | 21.0 | 20% | Ooze Shield | ABS | 12 | Yes | No | No | Yes | No | No | Yes | Yes | Yes | No | Yes | Yes | No | Yes | No | Yes | 12 | No | No | No | No | Yes | Yes | No | Yes | No | No | Yes | No | Yes | No | No | No | |||||||

| Raise3D PRO2 |  | £3778.80 | Powered Hotend Swap | Yes | Yes | 2 | 00:33:20 | 620 | 590 | 760 | Standard | 280 | 305 | 300 | 52.0 | 30% | Wipe tower | PC film | 5 | Yes | No | Yes | Yes | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | No | Yes | 12 | No | Yes | Yes | No | Yes | Yes | No | No | No | No | Yes | No | Yes | No | No | No | |||||||

| BCN3D Sigmax R19 |  | £3889.20 | Y axis only (IDEX) | Yes | No | 7 | 01:56:40 | 675 | 440 | 680 | Optional (+£300) | 420 | 297 | 210 | 18.0 | 10% | Dribble bin | Glass + Glue | 1 | Yes | No | Yes | No | Yes | No | Yes | Yes | Yes | Optional Nozzle (+£72) | Yes | Yes | Yes | No | No | Yes | 24 | No | No | No | No | Yes | No | No | No | No | No | No | No | Optional (+Enclosure £300) | No | No | No | |||||||

| Flashforge Creator Pro |  | £643.99 | Y axis motion only | Yes | No | 2 | 00:33:20 | 526 | 360 | 749 | Standard | 227 | 148 | 150 | 14.8 | 20% | Ooze Shield | Glass + Glue | 1 | No | No | Yes | Yes | Yes | No | Yes | No | No | No | No | Yes | No | No | No | No | 12 | No | No | No | No | Yes | No | No | No | No | No | No | No | No | No | No | No | |||||||

| Craftunique Craftbot3 |  | £2364.00 | Y axis only (IDEX) | Yes | No | 13 | 03:36:40 | 490 | 460 | 640 | Optional (+£300) | 270 | 250 | 250 | 32.0 | 30% | Wipe tower | PC film | 5 | Yes | No | Yes | Yes | Yes | No | Yes | No | Yes | No | Yes | Yes | Yes | Yes | No | Yes | 12 | No | No | Yes | Yes | Yes | No | No | No | Yes | Yes | Yes | Yes | Optional (+Enclosure £300) | Optional (+Enclosure) | Optional (+Enclosure) | No | |||||||

| Leapfrog Bolt Pro |  | £7221.90 | Y axis only (IDEX) | Yes | No | 7 | 01:56:40 | 723 | 831 | 801 | Standard | 300 | 320 | 205 | 64.0 | 10% | Dribble bin | PC film | 1 | Yes | No | No | Yes | No | No | Yes | Yes | Yes | Optional Nozzle (+£300) | Yes | No | No | Yes | No | Yes | 12 | No | Yes | Yes | No | Yes | No | Yes | No | No | No | No | No | Yes | Yes | No | No | |||||||

| Stratasys F170 |  | £19152.00 | Powered Hotend Swap | Yes | Yes | 7.15* | 01:59:10 | 711 | 864 | 1626 | Standard | 254 | 254 | 254 | 227.0 | 30% | Wipe tower | ABS | 1 | Yes | Yes | No | No | No | No | Yes | No | No | No | Yes | Yes | Yes | No | Yes | Yes | 12 | Yes | Yes | Yes | No | Yes | Yes | No | Yes | Yes | Yes | Yes | Yes | No | No | Yes | No | |||||||

| Dual Extrusion 3D Printer Comparison | Scaled image | Price £ Inc Tax | Dual Extrusion system | Stringing / Blobs | Nozzle lift | Seconds to swap material | hh:mm:ss added to example DM print | Printer Width mm | Printer Depth mm | Printer Height mm | Fully enclosed | Dual Extrusion Build Width | Dual Extrusion Build Depth | Dual Extrusion Build Height | Unboxed Weight. kg | Material waste per print % | Type of waste | Print Surface | Number of prints between maintenance | Removable | Flexible | Materials | 3rd party materials allowed? | 1.75mm Filament compatible | External filament feed | Dedicated material dehumidifier | Structural Material | ABS | Nylon | PETG / CPE | Abrasive filled | Flexible | Support Material | Water soluble PVA base eg PVOH/BVOH | Peel away | HIPS | Ethanol / diluted acid soluble | Software / Service | Software Included | Warranty length months | UK service centre | Connectivity | LAN | Wifi | Direct USB | SD card or USB stick | Automation | Levelling | Adaptive mapping | Material setting | Error resolution | User notification | File sending | Print statistics logging | Safety | HEPA Filter | Carbon Filter | Locking door | Automatic unlock |

Speed

Efficiency

Model+support / Waste

Stringing and blobs around the print create flaws on a surface. Unexpected structures on a print can easily lead to failure, wasting the whole print because it gets knocked off the build surface or is unusable. This is not shown in the data, failed prints means lost time and money. The solutions available for other printers are ooze shield / wipe tower / dribble bin. Each of these wastes material and still struggles to prevent stringing and blobs around the print.

Robox simply closes a valve on the nozzle when swapping materials, the result is faster, uses less material and creates far more successful prints.

Two Towers

Material change time effects total print time. To gather this data two towers 100mm tall are built side by side, each in a different material so all layers have the same properties and are sliced in 0.1mm layers. The material needs to change once every layer for 1000 layers to create the build, this includes nozzle motions and wipe tower type actions.